Vacuum step 1

foto by Tomas Mikule

Vacuum step 2

foto by Tomas Mikule

Vacuum step 3

foto by Tomas Mikule

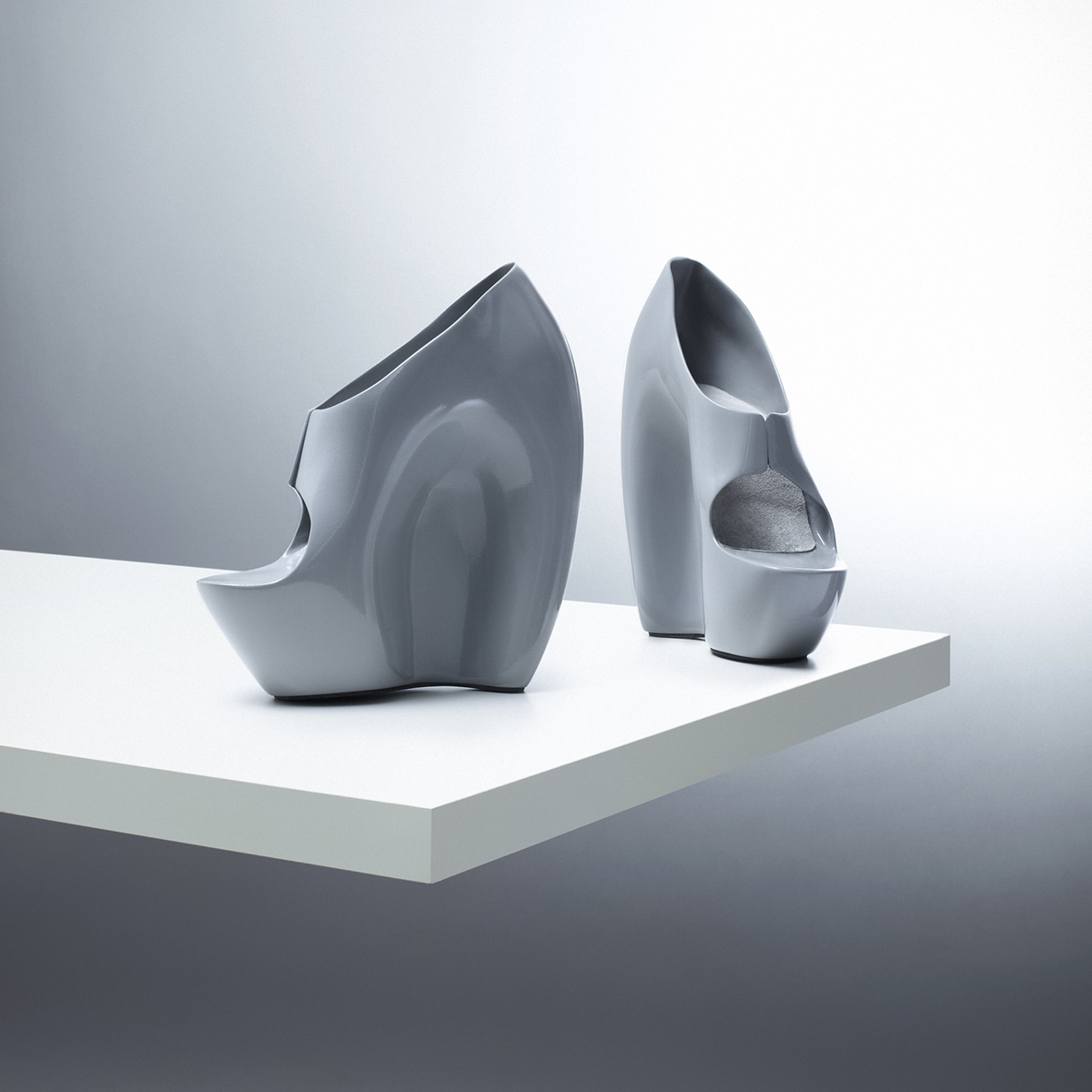

Walking carbon

foto by Tomas Mikule

Footprint 5

foto by Tomas Mikule

Footprint 6

foto by Tomas Mikule

Instant Shoe (thesis work)

3D printing, ABS vacuum shaping, carbon fiber lamination

"In the times of mass-production of everyday items, I feel the need to find a way back to their customization and individualisation.”

During the creation process of her thesis the designer realized that a commonly used boot structure is not an option, so she has cast her own feet, and according to those casts created a new shoe customized to her exact proportions.

With this first step an idea surfaced – due to new emerging technologies everyone can have their feet digitized in 3D and perfect-fitting shoes could be produced. It would not be a problem to change the design of the shoes (there could be even a library of designs on the Internet) and then manufacture the shoes exactly according to the desired proportions."

The main driving force has been the idea of where the technical innovations can bring the whole concept of (not only) shoe production.

Because of the new technologies (3D printing, ABS vacuum shaping, carbon fiber lamination) were used, a new construction solution for each pair must have been developed. Any splitting of the upper, lining, sole, heel as well as the zippers, underlay or any other additional support were canceled to develop shoe as one, almost sculptural, piece.

The designer have developed shell-like shape which feels like the shoe is the organic extension of the feet (model Vacuum step 1, Vacuum step 2). The second series, model Walking carbon, is kind of a “shoe skeleton” that holds the feet only at the necessary pressure points.

Another concept is Vacuum step 3 which uses the inner part as an exchangeable component so you can wear it as a pumps or wellingtons. The ultimate models are Footprint 5, which combines 3D print with classic shoe construction and finally Footprint 6 which is fully 3D printed showing that in the future the shape will not have to be subordinate to function.