Initial undertray design. Inlets placed at the sidepod entrance for packaging. The diffuser angle was tested from 9° to 16°.

Version2 of undertray design, optimum angle determined to be just shy of 15°, was set to 14.6° due to packaging.

Version4 of the undertray had a cambered keal at the nose to help feed the diffuser inlets.

Final CAD model ready for wind tunnel testing.

1/8th scale model made of ABS plastic, made using fused deposition modeling in-house.

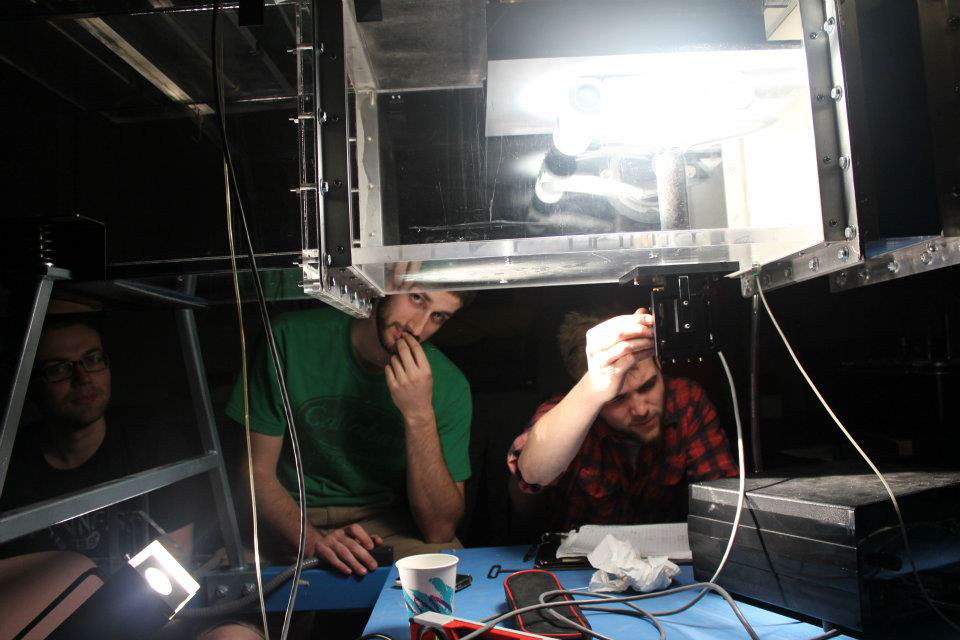

Scale model mounted in wind tunnel, designed a groundplane to mount the wheels and to prevent flow disruption.

Calibration

Undertray polystyrene mold.

1/8" pvc thermoformed core.

Undertray layed up, and vacuum bagged.

Thermoforming setup.

Final body mold cut into several sections, coated with over 8 layers of epoxy to prevent the polystyrene from melting during forming.

Panels formed, now ready for assembly.

Vinyl wrapped to and ready for competition.

Hand-made leather headrest with branded 1970's maverick logo.