Industrial ceiling mixer

This project was maid during my 3. semester at KADK. My class and I had as an overall subject: The commercial kitchen.

The first thing I did was go on a field study where I visited a lot of commercial kitchens in different sizes.

Field Study

During my field study I visited the Copenhagen University Hospital which is the biggest kitchen I have ever seen. It was more or less a factory for food. It had so much specialized equitment. Beside the hospital I visted a nursing home, a school and a day care. I found the day care to be the most interesting. So I went to visit some more daycares to see how the there were alike and where they was different.

One thing that I realized was that the daycares had a mix between industrial equitment and normal kitchen supplies. They were in so small kitchen that the industrial equiment often took up to much space or simply was ment to produce larger portions than needed. I now had an idea to what my problem definition should be.

"I will investigate the smaller commercial kitchens use of machinery. How this machinery is customized for kitchens of this size or that kitchens have use the services of machinery designed to either smaller or larger scale. I will look for the machines that create the biggest problems in their current form. I will look at the existing market and observe how industrial machines and private machines differ from each other. In order to be able to identify a how to design a machine addressed to the smaller sized commercial kitchen."

Specific area and machinery

To make my analysis easier I chose to work with just one daycare kitchen. This way I could easily grasp the specific problems that they had. One of the things I quickly discovered was that they had limited space. A machine that particularly caught my eye was their Bjørn Varimixer,. It stood on the floor on a little wagon and took up a lot of space even when it wasn't in use.. Beside the varimixer there was also a couple of other machines taking up tablespace.

Now I knew that I would try to take off from the varimixer. I wanted to try and integrate some of the others machines functionalities into the new design.

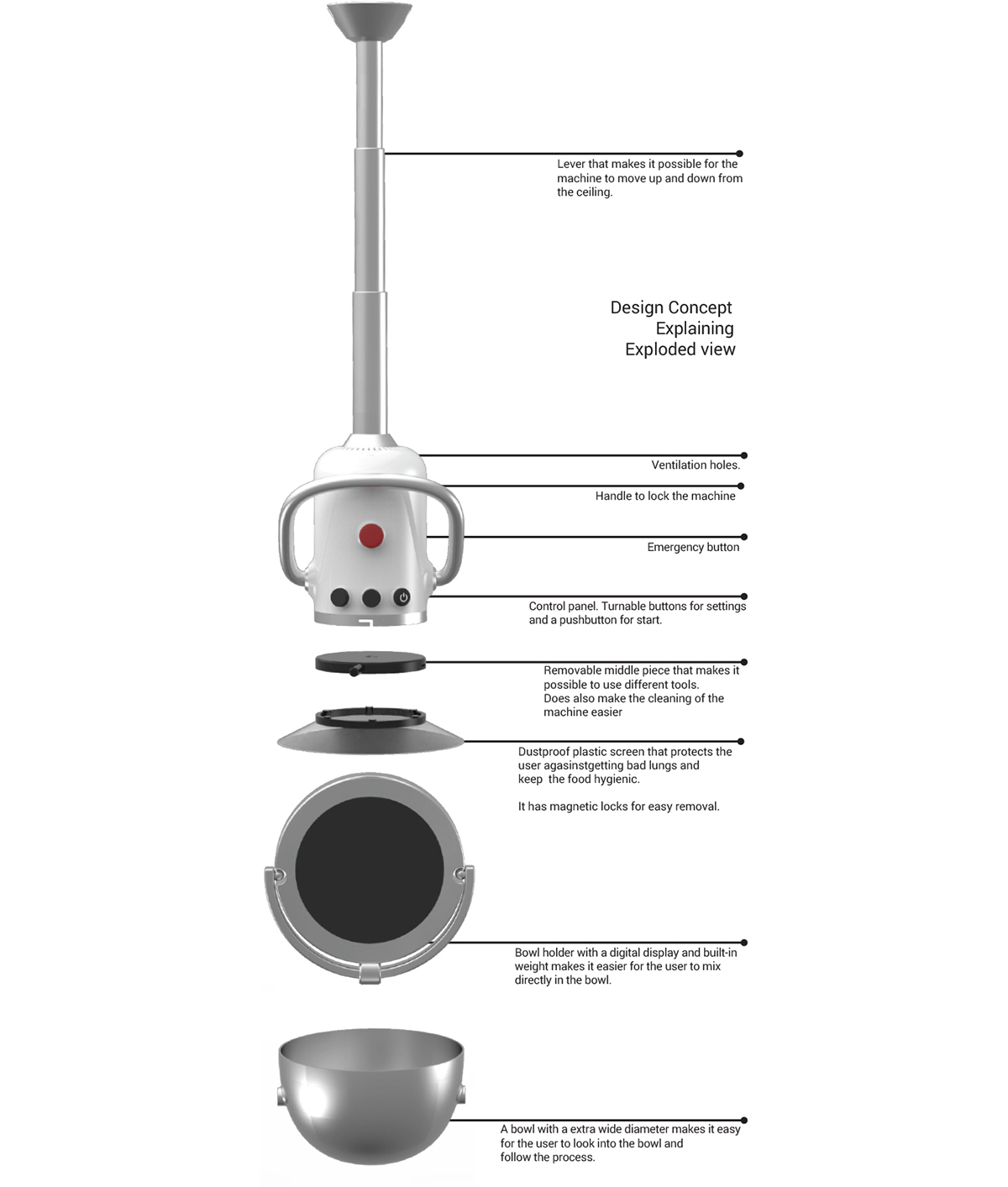

Most of all, the new machine should not take any table space when it is been used,

Visit at the Bjørn Varimixer factory

I contacted the manufacture of the Bjørn Varimixers and was lucky enough to be invited out to a meeting. At the meeting I heard a lot abouth their thoughts on their earlier designs. I also saw the sketches that a design firm had made during a redesign of one of the bigger mixers. When we went a tour around the factory I also got to see how the machines looked inside which gave me a good understanding on what was going on inside of the machine. I also learned a lot about the material used, hygiene and safety.

1. Powdercoated black steel

2. Stainless Steel

3. Ball polished aluminum

4. Plastic

The design of the machine

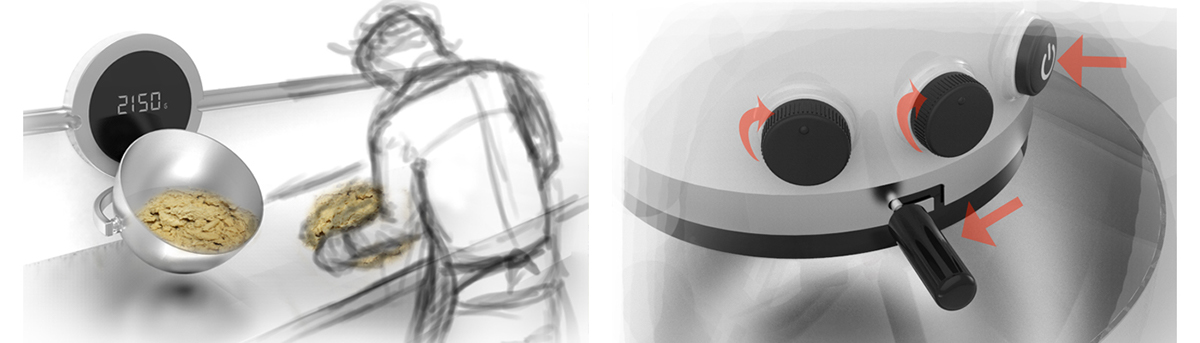

Now it was time to put all my collected knowledge into a product. However I chose to make it more important for me in this school projectt that it should end up with a product that would truly free up table space and increase the quality of the workflow. So therefor I didn't focus on the realism of my project. SO maybe you can't stabilize a machine like this from the ceiling. But if you never make a bit unrealistic product you will never move. I also chose that I wanted to use physical buttons insted of digital touch displays.

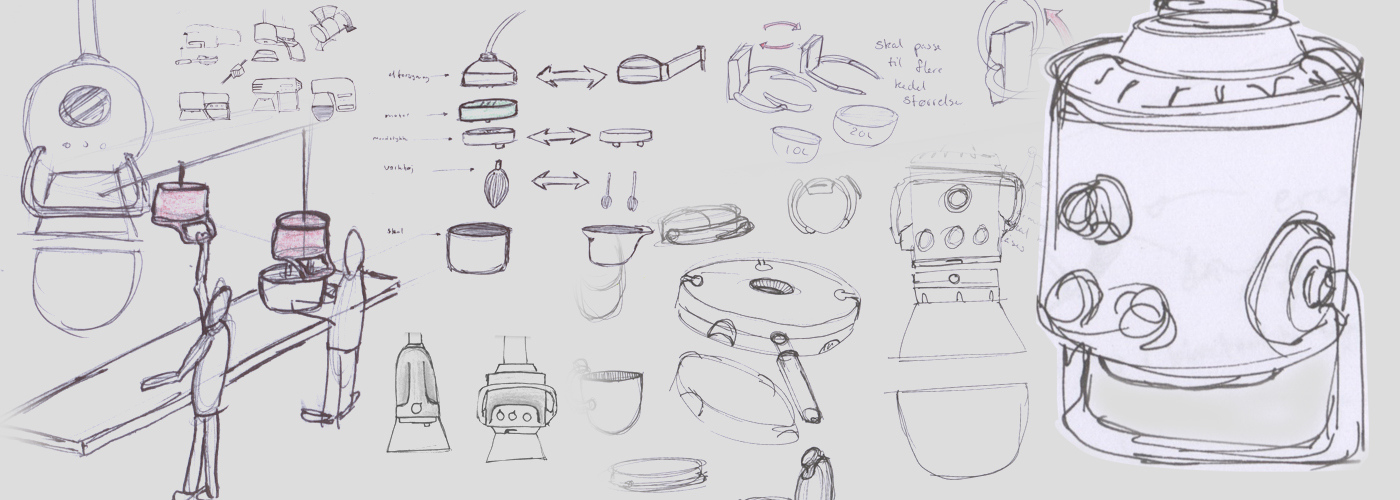

I made a lot of crazy form sketches along the way. I also did a lot of boring sketches of howthe system should work and which kind of buttons I should use before I went into 3d.

The final design

Thanks to all the places where you took the time to share your knowledge with me.